Jim's Machines and Accessories

High Quality made in Taiwan, spin riveting machine for many applications. Pneumatic or Hydraulic Ram depending on your application, mean the machine is energy efficient and easy to set and operate. Very accurate and will join your parts to pressure required with a fantastic finish. Join parts and eliminate play while allowing movement. Machine comes standard with the following - 5 deg Spin Head. - Riveting punch made from tool steel x 2 pieces. - Foot switch 2 hand control optional . - Operators manual. - Electric counter. - Lower die. - Lower die stand. Many types of punch are avail...

NSW

Unique bottom table electrode design suitable for virtually all applications. Metal furniture, light fixtures, electrical enclosures, 19 racks and wall mounted racks manufacturing can all benefit from the MySpot. Two standard table sizes are available starting from 800mm x 1000mm and 1000mm x 1500mm. Unique Easy Setting touch screen control means you welding in seconds with quality results. Tip dresser is also available. Weld quality is exceptional and no surface finishing is usually required as the table becomes the lower electrode. Operator can see clearly where to weld, as work is...

NSW

This new line of stud welding equipment meets the highest requirements due to operating convenience, low weight, high efficiency, compact design and absolute safety. The monitoring of all functions is clearly displayed by LED on the front panel. The short charging cycles increase productivity. Experience quality welds with excellent repeatability and high reliability. Nomark 65 can be used in both contact and gap welding automatically. Lightweight and easily portable, the NOMARK 65 weighs in at around half of many other conventional stud welding equipment. The NOMARK 65 is our capaci...

NSW

This line of stud welding equipment is a unique, microprocessor-controlled stud welding system with great versatility and near-perfect reliability. Features include Precise regulation and duration of weld current, immediate digital verification of all weld parameters, diagnosis of weld and system deviations, self-monitoring system... In other words, you ll get a perfect weld every time - or no weld at all. And in either case, you ll know why. Preset weld conditions can be stored for quick access when required. Very competitively priced, our welders perform and come with full factory ...

NSW

Patented WELLAIR air and moisture separator, is a low cost 100 reliable way to keep the compressed air being used by your CNC Machine clean and dry. WELLAIR is easy to install and comes complete with a mounting bracket. Unlike Line Filters and other types of filtering systems, the WELLAIR s performance remains constant regardless of the flow rate change, and best of all it requires no maitenance, and will not deteriorate over time. Even if you have line filters that require servicing to drain off collected water, WELLAIR will protect your investment even if maintenance to the line fi...

NSW

Why do the suppliers of refrigerated dryers also sell you line filters that require maintenace and the replacement of consummables on a regular basis Because moisture not only developes when the air is cooled after compression, it forms via condensation in your air line system. THE PIPES. WELL AIR has been designed to remove all moisture, dirt and oil from your compressed air line to protect your machinery and equipment from becoming contaminated. We have supplied 100 s of units already without one response that the WellAir didn t do what we say it will. This product removes 99.99 of...

NSW

Owner looking to move this machine urgently. Any reasonable offer will be considered Amada alpha II workhorse. Very reliable and very compact space saving design is perfect for the sheet metal job shop, or as a production machine. Machine has been serviced according to the manufacturer s recommendations, and has a complete documented history. Machine is not currently under power. This is an export model delivered new in October 1996. Control and oscillator are both Fanuc and oscillator power supplies have been replaced and have very low running hours since.

NSW

Loewer MiniSpin Joint has been developed to meet the needs for laser cut parts to have the starting and finishing tab removed in a safe and consistent way. Previous methods usually involved using offhand grinding where operator safety was always a constant issue. By utilizing disk technology, Loewer present an effective and safe way to remove edge joints and tabs from both thick and thin materials, easily and safely, while providing excellent and consistent results, even for unskilled operators. The Loewer MiniSpin Joint is affordable and provides peace of mind to the management, as ...

NSW

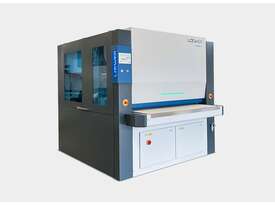

Latest Development from Loewer Germany is the RotoMaster Series of deburring and edge rounding machines. The RotoMaster comes in 3 variations an with 1500mm processing width to cater for the larger widths of sheetmetal sheets being used more commonly. The RotoMaster can apply a large radius to the edge of your parts quickly and evenly due to the excellent operational design features. Depending on the model, the Loewer RotoMaster can remove large cutting burrs, remove secondary burrs and provide large edge rounding, and apply a grained finish in a single setup. We are more than happy ...

NSW

Loewer developed the DiscMaster series to provide fast efficient deburring and edge rounding for parts cut by Laser, Plasma and Punching machines. With 3 models of DisMaster to choose from, the 6TD is the most capable model, being able to deburr, edge round and surface finish in a single setup. 3 rows of 2 disc each rotating discs each crisscrossing the feeding conveyor while the parts are fed through the machine, provide a uniform 360 degree result, so that any part is perfectly deburred, and edge rounded from all directions. By applying Loewer s patented orbital non directional fin...

NSW

The Loewer DisMaster model 2TD is an affordable and compact automatic deburring and edge rounding machine for all material types for parts cut or punched. Very easy to setup and operate, changing between material types is very fast. The DiscMaster design provides 360 degree processing as the disc units crisscross the feed conveyor while rotating. This also ensures that the abrasive discs wear evenly regardless of the size or position of the part on the conveyor. Excellent deburring of the primary burr at the first disc, while the second disc will remove the secondary burr and edge ro...

NSW

The Loewer DisMaster 4TD is the most popular model in the Loewer DiscMaster range of deburring and edge rounding machines for laser cut parts. Available in 1,000mm, 1500mm and even 2,000mm widths, it caters for the largest sheet metal applications. As in all DiscMaster models, the 4TD can process parts even as small as 20mm x 20mm. Disc technology has many advantages over wide belt processing, including even wear of all abrasives regardless the workpiece size, shape or position on the conveyor. With 2 rows of 2 discs crisscrossing the width of the feed conveyor while rotating, all pr...

NSW