Jim's Machines and Accessories

Produtech s patented system realizes the flexibility of using standard turret tooling systems to punch parts from coil rather than expensive flat sheet. huge cost savings are standard when purchasing coil as opposed to flat sheet Parts can be any length as the punching zone is incrementally moved. Shear cutoff is also available. There are a number of models available with standard arrangement catering for thickness up to 4.0mm mild steel x 1500mm width. All Electric means low noise, low running costs and low maintenance costs. Combination with a fiber laser is also a possibility, or ...

NSW

New from PRODUTECH, the ISEO coil fed Fiber Laser cutting system. Fast, reliable and clean cutting, a variety of parts can be cut quickly and accurately in most materials. Fiber laser systems are very reliable, and have very few consumables when compared to CO2 lasers. They can also cut alloys without the problems encounted by other laser types. Currently up to 3kW output, and materials up to 3.00mm thickness in coil widths of up to 1500mm as standard. Thicker materials are possible. This system will outperform plasma cutting machines and with huge reductions in material costs by usi...

NSW

New Swing Grinder from Loewer, Germany, is the ideal machine for deburring, polishing and linishing sheetmetal and small fabricated parts. Ideal for removing burrs and rounding edges, makes it perfect for any shop that laser cuts or punches parts. Even very small items can easily be processed without clamping. A double head that is supported by an articulated arm allows the operator to select the process or quickly change the method. A high grip table with perforations allows the parts to be deburred and the grinding dust to be collected by an easy access draw below the table, so cle...

NSW

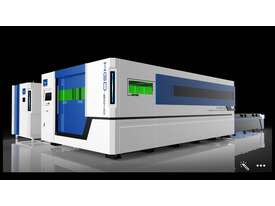

Welcome to the Future. - QY Laser Machines are Designed and Engineered to the highest level Excellent Manufacturer - Easy to own and Operate - Installation Training included - Advice and Application support - Quality is built in like no other machine from China - Specialist in Fiber Laser only - Available with Automatic Loading and Unloading - Full support and backup by experienced local Australian engineers - No obligation No pressure advice CALL US now You are more than welcome to visit the QY Laser Factory to inspect the design, engineering, and the quality of these machines. Fact...

NSW

TCE range of pitch controlled tapping machine are now available in Australia. Design is based on the out of production Brother Hi Tap series of machines and is manufactured in Taiwan using the original drawings and castings. Pitch control ensures precise thread cutting and adjustable clutch prevents tap breakage. Machines come in three size capacities and are priced very competitively. Model TT1-215 for tapping M2 to M8 Model TT2-225 for tapping M5 to M16 Model TT3-235 for tapping M10 to M32 Our standard machines come complete with foot switch, and a range of pitch gears and collets ...

NSW

Loewer DiscMaster series deburring and edge rounding machines provide the opportunity to automatically remove slag and dross quickly and safely, as well as environmentally friendly, without the use of wide belt abrasives and alike. All processing takes place with the enclosed machine covers without throwing grinding sparks and metal dust in conjunction with a dust extraction and filtering unit connected. The DiscMaster series machines can process part widths from 500mm through to 2000mm depending on the model. Additionally, all edges can have the slag removed and then edge rounded to...

NSW

The SwingGrinder M was developed expressly for the removal of slag from plasma and flame cut parts 4 to 5 times quicker than using an angle grinder or other manual methods. The design was based on the Loewer original SwingGrinder, extremely popular deburring and edge rounding machine for laser and punched sheetmetal parts. Parts are placed on the table and the operator passes the counterbalanced arm with a double ended spindle holding the abrasive tools across the top of the parts to remove the slag and by rotating the spindle 180 degrees all edges can be rounded. The first process r...

NSW

From Germany to Australia we present the cost effective Loewer DiscMaster ECO 2DBB sanding and denibbing machine. This machine is ideal for processing all types of timber including MDF following the machining and shaping process. A paint ready smooth finish to all exposed surfaces and edges is provided in one pass, due to the 3 stage sanding process that can access all exposed edges from 360 degrees. The result is a burr free edge and surface finish ready for painting. Finer finish for high level final painting can be achieved by reprocessing after undercoating to obtain an even fine...

NSW