Jim's Machines and Accessories

SAY GOOD BY TO BEND LINES, DIE MARKS in PRESS BRAKE FOLDING. Perfect for preventing die marks on prepainted materials, stainless steel and harder aluminum. Good to use with zinc coated materials especially when not being painted. Developed and made in Japan, Kizu-Non is a heat and abrasion resistant material that prevents bend lines and marking occurring caused by the shoulders of the die during bending. This material is very tough, and outlasts the traditional urethane film by 100 s of bends. Pricing is very efficient due to longevity and performance. The material comes in 5mtr and ...

NSW

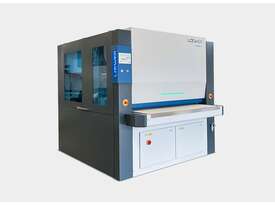

Euro Fintec has developed the Models 844, 845 and 846 to quickly and accurately deburr punched or sheared edges on sheetmetal parts. OH S as well as product liability responsibilities means that sharp and dangerous edges must be removed. Product quality also should drive responsible manufacturers to incorporate the deburring process into everyday manufacturing. The costs of deburring by manual methods are not only high but it is difficult to maintain consistency, so automation is the key in improving part quality. By improving part quality without adversely impacting on the cost of p...

NSW

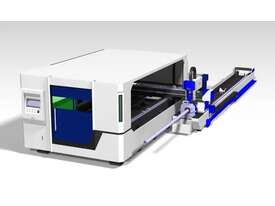

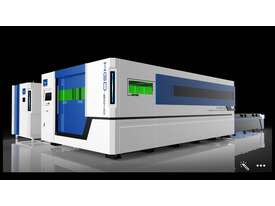

JMA proudly recommend the NEW QY Fiber Tube Laser Cutting Machines for Australian Industry. Very affordable and available in multiple configurations to suit your requirements. - Different models available in a variety of tube processing lengths and cutting diameter s. - Laser Power starting at 500W through to 6kW depending on material, wall thickness, and duty cycle. - Machines come complete with JMA standard package of chiller, dust collector, programming system, installation, training, service support and a peace of mind 2 year factory warranty. - Standard machines with manual load...

NSW

Fantastic Job Shop or Production Machine. Cut flat sheet or tube on the same affordable machine. Fabulous Fiber means virtually no maintenance required by the operator while cutting results are at the highest quality. JMA are proud to introduce the QY Laser Cutting Machine with running costs less than half of a CO2 laser cutting machine. QY are a Top Tier Laser Cutting Machine maker, specializing only in Fiber Laser. Their New 30,000sqm factory raises production capacity to 200 units per month. Our 30 years in CNC machinery and recent history helped us discover the leading design and...

NSW

INVESTMENT ALLOWANCE DEMONSTRATION MODEL AVAILABLE FOR IMMEDIATE DELIVERY. AS NEW, SAVE 2,000.00 off list price. Quality made machine tool for removing slag and dross from your laser table slats. Automatically adjusts to different widths and will not become jammed. Lightweight, and easy to operate, keeping the table slats clean improves the cutting quality and also extends the life of the table slats. Tool Steel horizontal cutters lift and scrape away stuck on slag and dross without operator effort. By using compressed air, the scraping action is extremely strong and will remove the ...

NSW

Welcome to the Future. - QY Laser Machines are Designed and Engineered to the highest level Excellent Manufacturer - Easy to own and Operate - Installation Training included - Advice and Application support - Quality is built in like no other machine from China - Specialist in Fiber Laser only - Available with Automatic Loading and Unloading - Full support and backup by experienced local Australian engineers - No obligation No pressure advice CALL US now You are more than welcome to visit the QY Laser Factory to inspect the design, engineering, and the quality of these machines. Fact...

NSW

Loewer DiscMaster series deburring and edge rounding machines provide the opportunity to automatically remove slag and dross quickly and safely, as well as environmentally friendly, without the use of wide belt abrasives and alike. All processing takes place with the enclosed machine covers without throwing grinding sparks and metal dust in conjunction with a dust extraction and filtering unit connected. The DiscMaster series machines can process part widths from 500mm through to 2000mm depending on the model. Additionally, all edges can have the slag removed and then edge rounded to...

NSW

The SwingGrinder M was developed expressly for the removal of slag from plasma and flame cut parts 4 to 5 times quicker than using an angle grinder or other manual methods. The design was based on the Loewer original SwingGrinder, extremely popular deburring and edge rounding machine for laser and punched sheetmetal parts. Parts are placed on the table and the operator passes the counterbalanced arm with a double ended spindle holding the abrasive tools across the top of the parts to remove the slag and by rotating the spindle 180 degrees all edges can be rounded. The first process r...

NSW

Loewer MiniSpin Joint has been developed to meet the needs for laser cut parts to have the starting and finishing tab removed in a safe and consistent way. Previous methods usually involved using offhand grinding where operator safety was always a constant issue. By utilizing disk technology, Loewer present an effective and safe way to remove edge joints and tabs from both thick and thin materials, easily and safely, while providing excellent and consistent results, even for unskilled operators. The Loewer MiniSpin Joint is affordable and provides peace of mind to the management, as ...

NSW

Latest Development from Loewer Germany is the RotoMaster Series of deburring and edge rounding machines. The RotoMaster comes in 3 variations an with 1500mm processing width to cater for the larger widths of sheetmetal sheets being used more commonly. The RotoMaster can apply a large radius to the edge of your parts quickly and evenly due to the excellent operational design features. Depending on the model, the Loewer RotoMaster can remove large cutting burrs, remove secondary burrs and provide large edge rounding, and apply a grained finish in a single setup. We are more than happy ...

NSW

Loewer developed the DiscMaster series to provide fast efficient deburring and edge rounding for parts cut by Laser, Plasma and Punching machines. With 3 models of DisMaster to choose from, the 6TD is the most capable model, being able to deburr, edge round and surface finish in a single setup. 3 rows of 2 disc each rotating discs each crisscrossing the feeding conveyor while the parts are fed through the machine, provide a uniform 360 degree result, so that any part is perfectly deburred, and edge rounded from all directions. By applying Loewer s patented orbital non directional fin...

NSW

The Loewer DisMaster model 2TD is an affordable and compact automatic deburring and edge rounding machine for all material types for parts cut or punched. Very easy to setup and operate, changing between material types is very fast. The DiscMaster design provides 360 degree processing as the disc units crisscross the feed conveyor while rotating. This also ensures that the abrasive discs wear evenly regardless of the size or position of the part on the conveyor. Excellent deburring of the primary burr at the first disc, while the second disc will remove the secondary burr and edge ro...

NSW