Jim's Machines and Accessories

CUB compact deburring machines come in 2 different sized models, 300mm width and 600mm width and can use a variety of abrasive products to achieve the finish that is required. Very fast and easy to set up, and with conveyor through feeding, these are very affordable deburring machines for any laser cutting shop. Thicknesses from 0.5mm to 300mm can be accommodated, and there is a minimum length of 100mm, while length is not restricted.

NSW

If your Amada Press Brake has major issues, especially with the Operatuer control, we have the solution to getting your machine back in production for a fraction of the cost of replacing the machine. If mechanically the machine is performing before the issue, we can get your machine going again. WE can bring your machine back to life with a new Australian made CNC, plus get rid of vulnerable relays board, with our very reliable replacement of the electrical box and its contents. See photos before and after. Retrofitted with New iCON CNC control, all new electricals, new LED lighting,...

NSW

Bend Line Sniper produces a laser beam to provide guidance to the operator of manual and CNC press brakes, by providing for accurate locating of the workpiece, especially when gauging the parts that are difficult due to shape or where alignment is usually done by marking off etc. Accuracy of the beam is achieved by clamping the unit as you would for the upper tool. The Bend Line Sniper can be shared among several machines using the same tool clamping system. Battery powered, the unit is kept recharged and ready to be used at any time with setup time minimal.

NSW

Loewer DiscMaster series deburring and edge rounding machines provide the opportunity to automatically remove slag and dross quickly and safely, as well as environmentally friendly, without the use of wide belt abrasives and alike. All processing takes place with the enclosed machine covers without throwing grinding sparks and metal dust in conjunction with a dust extraction and filtering unit connected. The DiscMaster series machines can process part widths from 500mm through to 2000mm depending on the model. Additionally, all edges can have the slag removed and then edge rounded to...

NSW

The SwingGrinder M was developed expressly for the removal of slag from plasma and flame cut parts 4 to 5 times quicker than using an angle grinder or other manual methods. The design was based on the Loewer original SwingGrinder, extremely popular deburring and edge rounding machine for laser and punched sheetmetal parts. Parts are placed on the table and the operator passes the counterbalanced arm with a double ended spindle holding the abrasive tools across the top of the parts to remove the slag and by rotating the spindle 180 degrees all edges can be rounded. The first process r...

NSW

Unique bottom table electrode design suitable for virtually all applications. Metal furniture, light fixtures, electrical enclosures, 19 racks and wall mounted racks manufacturing can all benefit from the MySpot. Two standard table sizes are available starting from 800mm x 1000mm and 1000mm x 1500mm. Unique Easy Setting touch screen control means you welding in seconds with quality results. Tip dresser is also available. Weld quality is exceptional and no surface finishing is usually required as the table becomes the lower electrode. Operator can see clearly where to weld, as work is...

NSW

TIG Plasma welding of corners is a basic requirement for most precision sheetmetal processing shops. Many corners are on basic rectangular shaped parts of varying heights, base materials and thickness. Although a basic requirement, skilled staff are required to ensure weld quality and neat and tidy appearance. From GECAM we present the CSW-150 Automatic Corner Welding System. Either TIG or Plasma power sources are intergarted into the machine, so programs can be created and stored for future recall should the same job be repeated in future times. Materials including mild steel, alumi...

NSW

Produtech s patented system realizes the flexibility of using standard turret tooling systems to punch parts from coil rather than expensive flat sheet. huge cost savings are standard when purchasing coil as opposed to flat sheet Parts can be any length as the punching zone is incrementally moved. Shear cutoff is also available. There are a number of models available with standard arrangement catering for thickness up to 4.0mm mild steel x 1500mm width. All Electric means low noise, low running costs and low maintenance costs. Combination with a fiber laser is also a possibility, or ...

NSW

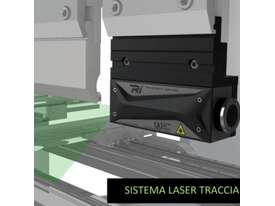

New from PRODUTECH, the ISEO coil fed Fiber Laser cutting system. Fast, reliable and clean cutting, a variety of parts can be cut quickly and accurately in most materials. Fiber laser systems are very reliable, and have very few consumables when compared to CO2 lasers. They can also cut alloys without the problems encounted by other laser types. Currently up to 3kW output, and materials up to 3.00mm thickness in coil widths of up to 1500mm as standard. Thicker materials are possible. This system will outperform plasma cutting machines and with huge reductions in material costs by usi...

NSW

New Swing Grinder from Loewer, Germany, is the ideal machine for deburring, polishing and linishing sheetmetal and small fabricated parts. Ideal for removing burrs and rounding edges, makes it perfect for any shop that laser cuts or punches parts. Even very small items can easily be processed without clamping. A double head that is supported by an articulated arm allows the operator to select the process or quickly change the method. A high grip table with perforations allows the parts to be deburred and the grinding dust to be collected by an easy access draw below the table, so cle...

NSW

SAY GOOD BY TO BEND LINES, DIE MARKS in PRESS BRAKE FOLDING. Perfect for preventing die marks on prepainted materials, stainless steel and harder aluminum. Good to use with zinc coated materials especially when not being painted. Developed and made in Japan, Kizu-Non is a heat and abrasion resistant material that prevents bend lines and marking occurring caused by the shoulders of the die during bending. This material is very tough, and outlasts the traditional urethane film by 100 s of bends. Pricing is very efficient due to longevity and performance. The material comes in 5mtr and ...

NSW

Euro Fintec has developed the Models 844, 845 and 846 to quickly and accurately deburr punched or sheared edges on sheetmetal parts. OH S as well as product liability responsibilities means that sharp and dangerous edges must be removed. Product quality also should drive responsible manufacturers to incorporate the deburring process into everyday manufacturing. The costs of deburring by manual methods are not only high but it is difficult to maintain consistency, so automation is the key in improving part quality. By improving part quality without adversely impacting on the cost of p...

NSW