Jim's Machines and Accessories

Scale Caliper

NewHigh Accuracy Measuring larger objects is always difficult, so Toei developed the Scale Caliper as a low cost way to acheive outstanding results. The pictures tell the story, a specially designed caliper system, made to fit a rule that has been designed to accept a T square. The components and accuracy meet JIS Japanese Industrial Standards . All components are made in Japan. Sizes Model No s are SC600, SC1,000, SC1,500, SC2,000 and SC3,000. Most sizes ex stock. We deliver anywhere, including international. Delivery charges will apply All prices are plus delivery and GST.

NSW

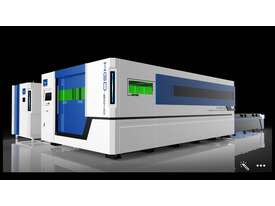

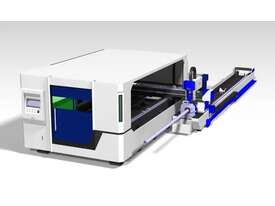

Welcome to the Future. - QY Laser Machines are Designed and Engineered to the highest level Excellent Manufacturer - Easy to own and Operate - Installation Training included - Advice and Application support - Quality is built in like no other machine from China - Specialist in Fiber Laser only - Available with Automatic Loading and Unloading - Full support and backup by experienced local Australian engineers - No obligation No pressure advice CALL US now You are more than welcome to visit the QY Laser Factory to inspect the design, engineering, and the quality of these machines. Fact...

NSW

Fantastic Job Shop or Production Machine. Cut flat sheet or tube on the same affordable machine. Fabulous Fiber means virtually no maintenance required by the operator while cutting results are at the highest quality. JMA are proud to introduce the QY Laser Cutting Machine with running costs less than half of a CO2 laser cutting machine. QY are a Top Tier Laser Cutting Machine maker, specializing only in Fiber Laser. Their New 30,000sqm factory raises production capacity to 200 units per month. Our 30 years in CNC machinery and recent history helped us discover the leading design and...

NSW

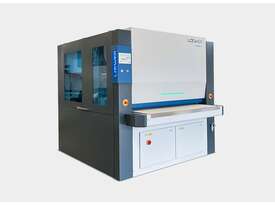

Loewer DiscMaster Series are designed to deburr and edge-round in a single pass. Removal of burrs splatter produced during laser, waterjet, flame and plasma cutting, or burrs in turret punch produced parts are removed in the first of a two or three step process depending on the model. 2 spindles driving abrasive discs, traverse the width of the feed through belt evenly removing the burrs before the next stage, again with 2 spindles traversing the feed through belt width produce a uniform 360deg rounded edge to all edges from all angles. Model 4TD provides 4 spindles as described. Mod...

NSW

Loewer MiniSpin Joint has been developed to meet the needs for laser cut parts to have the starting and finishing tab removed in a safe and consistent way. Previous methods usually involved using offhand grinding where operator safety was always a constant issue. By utilizing disk technology, Loewer present an effective and safe way to remove edge joints and tabs from both thick and thin materials, easily and safely, while providing excellent and consistent results, even for unskilled operators. The Loewer MiniSpin Joint is affordable and provides peace of mind to the management, as ...

NSW

Latest Development from Loewer Germany is the RotoMaster Series of deburring and edge rounding machines. The RotoMaster comes in 3 variations an with 1500mm processing width to cater for the larger widths of sheetmetal sheets being used more commonly. The RotoMaster can apply a large radius to the edge of your parts quickly and evenly due to the excellent operational design features. Depending on the model, the Loewer RotoMaster can remove large cutting burrs, remove secondary burrs and provide large edge rounding, and apply a grained finish in a single setup. We are more than happy ...

NSW

Loewer developed the DiscMaster series to provide fast efficient deburring and edge rounding for parts cut by Laser, Plasma and Punching machines. With 3 models of DisMaster to choose from, the 6TD is the most capable model, being able to deburr, edge round and surface finish in a single setup. 3 rows of 2 disc each rotating discs each crisscrossing the feeding conveyor while the parts are fed through the machine, provide a uniform 360 degree result, so that any part is perfectly deburred, and edge rounded from all directions. By applying Loewer s patented orbital non directional fin...

NSW

The Loewer DisMaster model 2TD is an affordable and compact automatic deburring and edge rounding machine for all material types for parts cut or punched. Very easy to setup and operate, changing between material types is very fast. The DiscMaster design provides 360 degree processing as the disc units crisscross the feed conveyor while rotating. This also ensures that the abrasive discs wear evenly regardless of the size or position of the part on the conveyor. Excellent deburring of the primary burr at the first disc, while the second disc will remove the secondary burr and edge ro...

NSW

The Loewer DisMaster 4TD is the most popular model in the Loewer DiscMaster range of deburring and edge rounding machines for laser cut parts. Available in 1,000mm, 1500mm and even 2,000mm widths, it caters for the largest sheet metal applications. As in all DiscMaster models, the 4TD can process parts even as small as 20mm x 20mm. Disc technology has many advantages over wide belt processing, including even wear of all abrasives regardless the workpiece size, shape or position on the conveyor. With 2 rows of 2 discs crisscrossing the width of the feed conveyor while rotating, all pr...

NSW

The popular Loewer Swing Grinder, has been customized to cater for Plasma and flame cut parts that present with heavy slag and dross. The M series has a magnetized table to hold the cut parts regardless of size during the deslagging and edge rounding process. Using the Hammer Disc, slag is quickly chipped away from holes edges, and by rotating the spindle head 180 degrees, the holes and edges can be deburred and edge rounded quickly and easily using the medium disc. The process will always be 3 or 4 times faster than methods such as chisels and angle grinders, and the Swing Grinder d...

NSW

Introducing the Italian designed portable work follower for press brakes. Easily installed to your existing CNC press brakes, the BF-01 provides an excellent addition to improve productivity, quality, and safety. Large and or heavy workpieces are difficult for even the strongest and skilled workers to manage. Thin sheet metal is very awkward to bend, requiring support to prevent the back braking situation for both the workpiece and the operator. Holding and lowering this type of workpiece after bending is high risk for injuries. Why risk the health and safety of your most important e...

NSW

Unique design patented by Koyo Giken of Japan. Designed and made in Japan, the MySpot series of high quality spot welding machines has revolutionized the spot welding of sheet metal enclosures, items related to furniture, light fittings, and many other general purpose applications. Using the horizontal gun allows easy access into enclosures with the operator having a clear view on where to weld, as the workpiece is located on the lower electrode. Perfect welding is a feature, as is virtually zero distortion and very little dressing. Machines equipped with the vertical gun allow acces...

NSW