Jim's Machines and Accessories

We now supply replacement TFT screens to replace your dead CRT monitors on your Lathe and Machining Centre CNC controls. Both monochrome and colour are available, and replacement comes completely ready to plug in with no modifications or adjustments neccessary. We can supply replacements for most brands of machine control. So if your screen is burned or failing and hard to read, we can supply brand new TFT screens to refresh your machine. All screens are manufactured in Germany and come complete with warranty. Prices will vary according to size and type.

NSW

Unique design suitable for virtually all applications. Two standard table sizes are available starting from 800mm x 1000mm and 1000mm x 1500mm. Models with Horizontal Gun only or in combination with a Vertical Gun, just about any product can be processed on our machines. Unique Easy Setting touch screen control means you welding in seconds with quality results. Weld quality is exceptional and no distortion due to table support, while little surface finishing of the weld is required as the table is the lower electrode. Add to that the best electrode cooling system, means life of consu...

NSW

High Quality made in Taiwan, spin riveting machine for many applications. Pneumatic or Hydraulic Ram depending on your application, mean the machine is energy efficient and easy to set and operate. Very accurate and will join your parts to pressure required with a fantastic finish. Join parts and eliminate play while allowing movement. Machine comes standard with the following - 5 deg Spin Head. - Riveting punch made from tool steel x 2 pieces. - Foot switch 2 hand control optional . - Operators manual. - Electric counter. - Lower die. - Lower die stand. Many types of punch are avail...

NSW

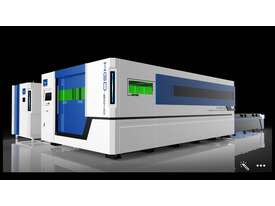

Welcome to the Future. - QY Laser Machines are Designed and Engineered to the highest level Excellent Manufacturer - Easy to own and Operate - Installation Training included - Advice and Application support - Quality is built in like no other machine from China - Specialist in Fiber Laser only - Available with Automatic Loading and Unloading - Full support and backup by experienced local Australian engineers - No obligation No pressure advice CALL US now You are more than welcome to visit the QY Laser Factory to inspect the design, engineering, and the quality of these machines. Fact...

NSW

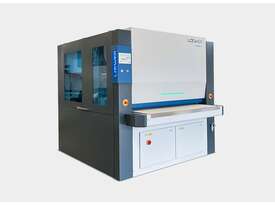

CUB compact deburring machines come in 2 different sized models, 300mm width and 600mm width and can use a variety of abrasive products to achieve the finish that is required. Very fast and easy to set up, and with conveyor through feeding, these are very affordable deburring machines for any laser cutting shop. Thicknesses from 0.5mm to 300mm can be accommodated, and there is a minimum length of 100mm, while length is not restricted.

NSW

Hand Held Fiber Laser Welding Machine, complete with all accessories required to process most workpieces and materials. Expect exceptional results where TIG welding is commonly used. Highest penetration with smallest heat affected zone provides the highest quality welds possible by hand. Required skills are minimal, due to purpose designed nozzles used to guide the torch and maintain focal point continuously. Most metals can be processed with standout finishes being achieved at 3 or 4 times the speeds of TIG welding. Less Welding time, less Dressing time provides higher productivity,...

NSW

Loewer MiniSpin Joint has been developed to meet the needs for laser cut parts to have the starting and finishing tab removed in a safe and consistent way. Previous methods usually involved using offhand grinding where operator safety was always a constant issue. By utilizing disk technology, Loewer present an effective and safe way to remove edge joints and tabs from both thick and thin materials, easily and safely, while providing excellent and consistent results, even for unskilled operators. The Loewer MiniSpin Joint is affordable and provides peace of mind to the management, as ...

NSW

Latest Development from Loewer Germany is the RotoMaster Series of deburring and edge rounding machines. The RotoMaster comes in 3 variations an with 1500mm processing width to cater for the larger widths of sheetmetal sheets being used more commonly. The RotoMaster can apply a large radius to the edge of your parts quickly and evenly due to the excellent operational design features. Depending on the model, the Loewer RotoMaster can remove large cutting burrs, remove secondary burrs and provide large edge rounding, and apply a grained finish in a single setup. We are more than happy ...

NSW

Loewer developed the DiscMaster series to provide fast efficient deburring and edge rounding for parts cut by Laser, Plasma and Punching machines. With 3 models of DisMaster to choose from, the 6TD is the most capable model, being able to deburr, edge round and surface finish in a single setup. 3 rows of 2 disc each rotating discs each crisscrossing the feeding conveyor while the parts are fed through the machine, provide a uniform 360 degree result, so that any part is perfectly deburred, and edge rounded from all directions. By applying Loewer s patented orbital non directional fin...

NSW

The Loewer DisMaster model 2TD is an affordable and compact automatic deburring and edge rounding machine for all material types for parts cut or punched. Very easy to setup and operate, changing between material types is very fast. The DiscMaster design provides 360 degree processing as the disc units crisscross the feed conveyor while rotating. This also ensures that the abrasive discs wear evenly regardless of the size or position of the part on the conveyor. Excellent deburring of the primary burr at the first disc, while the second disc will remove the secondary burr and edge ro...

NSW

The Loewer DisMaster 4TD is the most popular model in the Loewer DiscMaster range of deburring and edge rounding machines for laser cut parts. Available in 1,000mm, 1500mm and even 2,000mm widths, it caters for the largest sheet metal applications. As in all DiscMaster models, the 4TD can process parts even as small as 20mm x 20mm. Disc technology has many advantages over wide belt processing, including even wear of all abrasives regardless the workpiece size, shape or position on the conveyor. With 2 rows of 2 discs crisscrossing the width of the feed conveyor while rotating, all pr...

NSW

The popular Loewer Swing Grinder, has been customized to cater for Plasma and flame cut parts that present with heavy slag and dross. The M series has a magnetized table to hold the cut parts regardless of size during the deslagging and edge rounding process. Using the Hammer Disc, slag is quickly chipped away from holes edges, and by rotating the spindle head 180 degrees, the holes and edges can be deburred and edge rounded quickly and easily using the medium disc. The process will always be 3 or 4 times faster than methods such as chisels and angle grinders, and the Swing Grinder d...

NSW