Jim's Machines and Accessories

Smart Pressure Controlled Spot Welding Machine from Japan. Available with variety of power supplies. AC 30kVA single phase maximum current 10000amps 2.2kN pressure Inverter 40kVA 3 phase maximum current 12000 amps 2.2kN pressure Inverter 80kVA 3 phase maximum current 24000 amps 3.8kN pressure Inverter models feature unique technology High Speed Welding patented. - No Burn or Distortion even zinc surfaces show no oxidization - Stronger Welds with no separation - Direct Current - Short Weld Time - Large Output Current - Controlled Waveform - Energy Saving - Touch Screen 3 step Control ...

NSW

Desk Top Spot Weld Tester features - 2kN - 30kN measuring capacity - Digital load indication - Equipped with Printer for secure record - Hydraulic Jack provides the force needed - Space Saving Design and easily portable - Weight 68kg Dimensions H800mm x W460mm x D400mm

NSW

Loewer DiscMaster Series are designed to deburr and edge-round in a single pass. Removal of burrs splatter produced during laser, waterjet, flame and plasma cutting, or burrs in turret punch produced parts are removed in the first of a two or three step process depending on the model. 2 spindles driving abrasive discs, traverse the width of the feed through belt evenly removing the burrs before the next stage, again with 2 spindles traversing the feed through belt width produce a uniform 360deg rounded edge to all edges from all angles. Model 4TD provides 4 spindles as described. Mod...

NSW

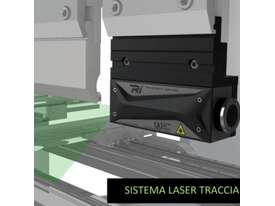

Bend Line Sniper produces a laser beam to provide guidance to the operator of manual and CNC press brakes, by providing for accurate locating of the workpiece, especially when gauging the parts that are difficult due to shape or where alignment is usually done by marking off etc. Accuracy of the beam is achieved by clamping the unit as you would for the upper tool. The Bend Line Sniper can be shared among several machines using the same tool clamping system. Battery powered, the unit is kept recharged and ready to be used at any time with setup time minimal.

NSW

Owner looking to move this machine urgently. Any reasonable offer will be considered Amada alpha II workhorse. Very reliable and very compact space saving design is perfect for the sheet metal job shop, or as a production machine. Machine has been serviced according to the manufacturer s recommendations, and has a complete documented history. Machine is not currently under power. This is an export model delivered new in October 1996. Control and oscillator are both Fanuc and oscillator power supplies have been replaced and have very low running hours since.

NSW

Loewer MiniSpin Joint has been developed to meet the needs for laser cut parts to have the starting and finishing tab removed in a safe and consistent way. Previous methods usually involved using offhand grinding where operator safety was always a constant issue. By utilizing disk technology, Loewer present an effective and safe way to remove edge joints and tabs from both thick and thin materials, easily and safely, while providing excellent and consistent results, even for unskilled operators. The Loewer MiniSpin Joint is affordable and provides peace of mind to the management, as ...

NSW

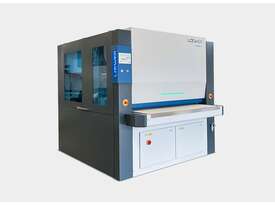

Latest Development from Loewer Germany is the RotoMaster Series of deburring and edge rounding machines. The RotoMaster comes in 3 variations an with 1500mm processing width to cater for the larger widths of sheetmetal sheets being used more commonly. The RotoMaster can apply a large radius to the edge of your parts quickly and evenly due to the excellent operational design features. Depending on the model, the Loewer RotoMaster can remove large cutting burrs, remove secondary burrs and provide large edge rounding, and apply a grained finish in a single setup. We are more than happy ...

NSW

Loewer developed the DiscMaster series to provide fast efficient deburring and edge rounding for parts cut by Laser, Plasma and Punching machines. With 3 models of DisMaster to choose from, the 6TD is the most capable model, being able to deburr, edge round and surface finish in a single setup. 3 rows of 2 disc each rotating discs each crisscrossing the feeding conveyor while the parts are fed through the machine, provide a uniform 360 degree result, so that any part is perfectly deburred, and edge rounded from all directions. By applying Loewer s patented orbital non directional fin...

NSW

The Loewer DisMaster model 2TD is an affordable and compact automatic deburring and edge rounding machine for all material types for parts cut or punched. Very easy to setup and operate, changing between material types is very fast. The DiscMaster design provides 360 degree processing as the disc units crisscross the feed conveyor while rotating. This also ensures that the abrasive discs wear evenly regardless of the size or position of the part on the conveyor. Excellent deburring of the primary burr at the first disc, while the second disc will remove the secondary burr and edge ro...

NSW

The Loewer DisMaster 4TD is the most popular model in the Loewer DiscMaster range of deburring and edge rounding machines for laser cut parts. Available in 1,000mm, 1500mm and even 2,000mm widths, it caters for the largest sheet metal applications. As in all DiscMaster models, the 4TD can process parts even as small as 20mm x 20mm. Disc technology has many advantages over wide belt processing, including even wear of all abrasives regardless the workpiece size, shape or position on the conveyor. With 2 rows of 2 discs crisscrossing the width of the feed conveyor while rotating, all pr...

NSW

The popular Loewer Swing Grinder, has been customized to cater for Plasma and flame cut parts that present with heavy slag and dross. The M series has a magnetized table to hold the cut parts regardless of size during the deslagging and edge rounding process. Using the Hammer Disc, slag is quickly chipped away from holes edges, and by rotating the spindle head 180 degrees, the holes and edges can be deburred and edge rounded quickly and easily using the medium disc. The process will always be 3 or 4 times faster than methods such as chisels and angle grinders, and the Swing Grinder d...

NSW

Introducing the Italian designed portable work follower for press brakes. Easily installed to your existing CNC press brakes, the BF-01 provides an excellent addition to improve productivity, quality, and safety. Large and or heavy workpieces are difficult for even the strongest and skilled workers to manage. Thin sheet metal is very awkward to bend, requiring support to prevent the back braking situation for both the workpiece and the operator. Holding and lowering this type of workpiece after bending is high risk for injuries. Why risk the health and safety of your most important e...

NSW