Jim's Machines and Accessories

TIG Plasma welding of corners is a basic requirement for most precision sheetmetal processing shops. Many corners are on basic rectangular shaped parts of varying heights, base materials and thickness. Although a basic requirement, skilled staff are required to ensure weld quality and neat and tidy appearance. From GECAM we present the CSW-150 Automatic Corner Welding System. Either TIG or Plasma power sources are intergarted into the machine, so programs can be created and stored for future recall should the same job be repeated in future times. Materials including mild steel, alumi...

NSW

Produtech s patented system realizes the flexibility of using standard turret tooling systems to punch parts from coil rather than expensive flat sheet. huge cost savings are standard when purchasing coil as opposed to flat sheet Parts can be any length as the punching zone is incrementally moved. Shear cutoff is also available. There are a number of models available with standard arrangement catering for thickness up to 4.0mm mild steel x 1500mm width. All Electric means low noise, low running costs and low maintenance costs. Combination with a fiber laser is also a possibility, or ...

NSW

New from PRODUTECH, the ISEO coil fed Fiber Laser cutting system. Fast, reliable and clean cutting, a variety of parts can be cut quickly and accurately in most materials. Fiber laser systems are very reliable, and have very few consumables when compared to CO2 lasers. They can also cut alloys without the problems encounted by other laser types. Currently up to 3kW output, and materials up to 3.00mm thickness in coil widths of up to 1500mm as standard. Thicker materials are possible. This system will outperform plasma cutting machines and with huge reductions in material costs by usi...

NSW

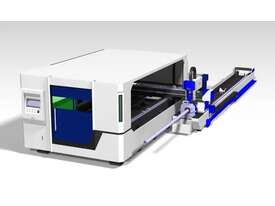

JMA proudly recommend the NEW QY Fiber Tube Laser Cutting Machines for Australian Industry. Very affordable and available in multiple configurations to suit your requirements. - Different models available in a variety of tube processing lengths and cutting diameter s. - Laser Power starting at 500W through to 6kW depending on material, wall thickness, and duty cycle. - Machines come complete with JMA standard package of chiller, dust collector, programming system, installation, training, service support and a peace of mind 2 year factory warranty. - Standard machines with manual load...

NSW

Fantastic Job Shop or Production Machine. Cut flat sheet or tube on the same affordable machine. Fabulous Fiber means virtually no maintenance required by the operator while cutting results are at the highest quality. JMA are proud to introduce the QY Laser Cutting Machine with running costs less than half of a CO2 laser cutting machine. QY are a Top Tier Laser Cutting Machine maker, specializing only in Fiber Laser. Their New 30,000sqm factory raises production capacity to 200 units per month. Our 30 years in CNC machinery and recent history helped us discover the leading design and...

NSW

Euro Fintec has developed the Models 844, 845 and 846 to quickly and accurately deburr punched or sheared edges on sheetmetal parts. OH S as well as product liability responsibilities means that sharp and dangerous edges must be removed. Product quality also should drive responsible manufacturers to incorporate the deburring process into everyday manufacturing. The costs of deburring by manual methods are not only high but it is difficult to maintain consistency, so automation is the key in improving part quality. By improving part quality without adversely impacting on the cost of p...

NSW

Euro Fintec have developed the compact Model 131 to create consistant finishing of corner welded sheetmetal parts. Unique design allows for quick and easy adjustment to linish away the welded corner, while leaving a desired radius. With an adjustable Radius starting from 1 to a maximum of 10mm, the part can be up to 150mm in height. The part is presented to the patented ocsillating belt head by the operator using the simple and effective side guidance mounted of the height adjustable work table. Turn welded corners quickly and consistantly, into finished corners without relying on sk...

NSW

Unique bottom table electrode design suitable for virtually all applications. Metal furniture, light fixtures, electrical enclosures, 19 racks and wall mounted racks manufacturing can all benefit from the MySpot. Two standard table sizes are available starting from 800mm x 1000mm and 1000mm x 1500mm. Unique Easy Setting touch screen control means you welding in seconds with quality results. Tip dresser is also available. Weld quality is exceptional and no surface finishing is usually required as the table becomes the lower electrode. Operator can see clearly where to weld, as work is...

NSW

This new line of stud welding equipment meets the highest requirements due to operating convenience, low weight, high efficiency, compact design and absolute safety. The monitoring of all functions is clearly displayed by LED on the front panel. The short charging cycles increase productivity. Experience quality welds with excellent repeatability and high reliability. Nomark 65 can be used in both contact and gap welding automatically. Lightweight and easily portable, the NOMARK 65 weighs in at around half of many other conventional stud welding equipment. The NOMARK 65 is our capaci...

NSW

This line of stud welding equipment is a unique, microprocessor-controlled stud welding system with great versatility and near-perfect reliability. Features include Precise regulation and duration of weld current, immediate digital verification of all weld parameters, diagnosis of weld and system deviations, self-monitoring system... In other words, you ll get a perfect weld every time - or no weld at all. And in either case, you ll know why. Preset weld conditions can be stored for quick access when required. Very competitively priced, our welders perform and come with full factory ...

NSW

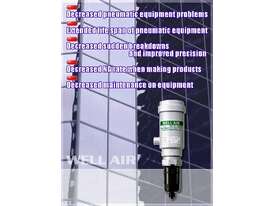

Patented WELLAIR air and moisture separator, is a low cost 100 reliable way to keep the compressed air being used by your CNC Machine clean and dry. WELLAIR is easy to install and comes complete with a mounting bracket. Unlike Line Filters and other types of filtering systems, the WELLAIR s performance remains constant regardless of the flow rate change, and best of all it requires no maitenance, and will not deteriorate over time. Even if you have line filters that require servicing to drain off collected water, WELLAIR will protect your investment even if maintenance to the line fi...

NSW

Why do the suppliers of refrigerated dryers also sell you line filters that require maintenace and the replacement of consummables on a regular basis Because moisture not only developes when the air is cooled after compression, it forms via condensation in your air line system. THE PIPES. WELL AIR has been designed to remove all moisture, dirt and oil from your compressed air line to protect your machinery and equipment from becoming contaminated. We have supplied 100 s of units already without one response that the WellAir didn t do what we say it will. This product removes 99.99 of...

NSW